Problem-Solving Series #1: SLPE Optimises Grouted Connections Through R&D and FEA

Background

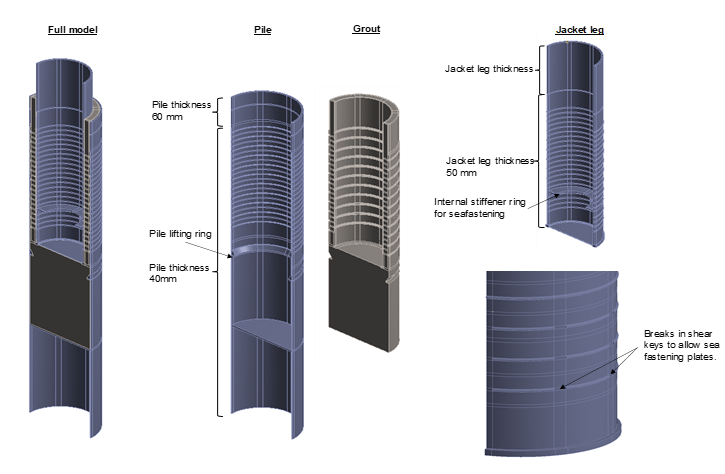

Monopile-to-transition piece grouted connections: straight-sided with shear keys, or, conical

Pile-to-jacket leg grouted connections for both pre- and post-piled jackets.

Grouted connections are formed of two concentric structural steel tubular or conical members, where the annulus between the outer and inner members is filled with grout. The behaviour of grouted connections in offshore applications has been and continues to be the subject of numerous studies, research papers and industry conferences.

Problem Statement

Grouted connections have traditionally been designed using empirical formulae based on tests. A Joint Industry Project (JIP) was recently completed to assess the capacity of straight-sided grouted connections with shear keys subject to high bending moments. The findings from this JIP have now been incorporated in the current design standards. The empirical formulae, however, present some validity limits on the geometry, grout strength and contact pressures between the grout and steel members.

Finite Element Analysis (FEA)

Grout is a brittle material that exhibits low tensile strength and comparatively high strength in compression. In compression, grout experiences non-linear hardening followed by exponential softening behaviour and eventually fails through crushing. In tension, once the tensile limit is reached, the material exhibits exponential softening behaviour with an almost immediate transition into the softening regime. This behaviour is caused by cracking within the brittle material and is often numerically difficult to converge to a solution.

SLPE’s grout constitutive models include the full hardening and softening behaviour in both compression and tension in order to accurately simulate the grout behaviour. We carry out material model calibration tests to verify the correct material behaviour in line with available test data, material data sheets, and/or concrete codes prior to assessment of the grouted connection.

We use non-linear FEA models in order to accurately investigate both global and localised effects including aspects not usually considered within empirical formulae given in design standards. These include:

In-depth insight into the load transfer mechanism, e.g. around shear keys.

The use of extra high strength grout products outside the validity range of empirical formulae given in design standards.

The combined installation tolerances, e.g. pile verticality combined with concentricity tolerances may lead to reduced grout thickness outside the abovementioned validity ranges.

The presence of installation aids such as centralisers.

Solutions for temporary attachments to aid fabrication and installation, e.g. temporary sea fastening weldments to jacket legs in pre-piled jackets may require breaks within some of the shear keys within the grouted connection zone.

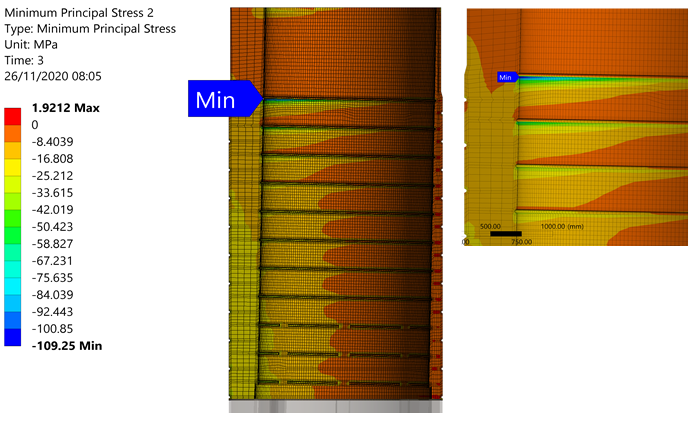

The following plots present an example of a jacket leg-to-pile grouted connection for a pre-piled jacket.

A plot of tensile stresses within the grout body considering worst-case installation tolerances.

A plot of compressive stresses within the grout body considering worst-case installation tolerances.

Conclusion

Navraj Sokhi, FEA Specialist at SLPE said: “SLPE’s material calibration studies and non-linear FEA have enabled us to gain a deeper understanding of grouted connection behaviour and focus on specific critical areas for design optimisation. This has enabled us to overcome the limitations and conservatism present in conventional design methods, whilst ensuring a high degree of confidence in the structural performance.”

By designing a robust structure with the minimum amount of grout, we help our clients to achieve cost-effective grouted connection designs that minimise installation risks.